I recently experienced and fixed the P0321 / 16705 fault code on my Skoda Fabia VRS 1.9 TDI with the PD130 BLT engine. This engine is the extremely common VAG PD 1.9 turbo charged diesel engine as used in many models of VW/Audi/Skoda.

During diagnosis of this problem I did a lot of research concerning the P0321 fault code which is for the G28 engine speed sensor implausible signal which I thought I would share, as well as what the final solution to the problem was.

The ross-tech wiki lists the following information regarding this code:

P0321 / 16705 fault code information

Possible Symptoms

- Engine shuts off

- Engine doesn't start

- Speedometer inoperative

- Glow Plug Indicator Lamp (K29) flashes

Possible Causes

- Engine Speed Sensor (G28) loose

- Engine Speed Sensor (G28) faulty

Possible Solutions

- Check Engine Speed Sensor (G28)

Special Notes

- The Engine Speed Sensor (G28) is also used as a reference sensor for the crankshaft position and correlates with the Camshaft Position Sensor Bank 1 (G40) and Camshaft Position Sensor Bank 2 (G163).

- When an engine will not start due to mechanical (spark/fuel/compression/timing) related issues it is not uncommon to set a false G28 fault codes due to extended cranking with a no-start condition.

My symptoms:

- The car would not rev above approximately 3400rpm

- If you tried to rev over 3400rpm the limiter would cut in and it would trigger the 16705 fault code.

- This fault code would illuminate the check engine management light and also flashing glow plug light.

- Once the fault code was triggered you would not rev over approx 3400rpm.

- If you did not rev over 3400rpm you could drive the car as normal.

- Car would start without hesitation hot or cold.

On these engines the ECU uses the values from the G28 crankshaft position sensor and G40 camshaft position sensor to determine crank angle relative to camshaft angle. In VCDS this is known as torsion value or syncro angle.

Because the ECU looks at the relationship between these two values, if one value is implausible then it will struggle to tell which sensor is at fault. In my case it is suggesting that the value from the G28 sensor does not match the value from the G40 sensor.

The fault code first appeared after I had the timing belt changed and I also changed the thermostat.

As this issue is related to timing my first thoughts were that it was something to do with the timing belt change. Perhaps the timing was not correct or the belt tension was wrong or the camshaft sensor had been knocked during the work.

Looking into this further I removed the top timing belt cover and checked the timing belt tension as well as the little tabs which are on the engine side of the camshaft pulley - these are used by the G40 sensor and if one of them was bent this might prevent the sensor from reading the position correctly. No problems found.

I also read the syncro angle using VCDS and it was fluctuating between -1.1KW and -1.7KW which is within range - this rules out the timing being incorrect.

I also had to change the thermostat around the same time. The thermostat on this engine is on the front of the engine to the left hand side which is close to where the wire for the G28 crankshaft sensor runs from the plug at the top to the sensor position at the bottom under the oil cooler.

Solution

In the end the G28 crankshaft sensor was faulty and I think it was caused by coolant running down the cable sheath and going directly into the sensor itself...or it could just be a coincidence.

Once the G28 sensor was replaced with a genuine VW item the issue was cured completely.

|

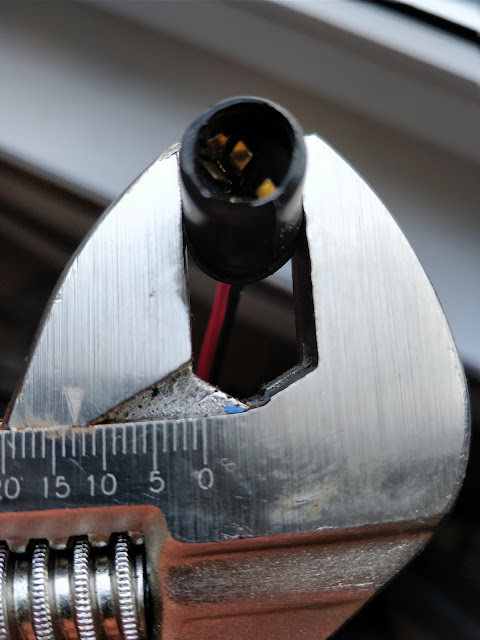

| G28 crankshaft sensor location behind oil cooler |